The use of polymeric materials in automobiles has experienced a boom lately. The number of vehicles using such materials has increased and continues to do so. The increasing demand for automobiles with more features has led to an increase in the applications of polymers in the automobile industry.

The automobile industry is highly diversified in its application of polymer engineering. Because of flexibility, durability and ruggedness, polymeric materials are used in many ways. It can be found almost everywhere in automobiles, from the dashboard, bumpers and door panels to the exterior body and much more. They are the second most commonly used materials in automobiles. These products are flexible enough to withstand daily use over the life of an automobile.

LLDPE suppliers in India are getting more business than ever with so much demand for polymers. The number of polymer companies established over the last decade would surprise you. One such polymer dealer that is making very rapid advancements in the polymer sector is Sun Polymers.

Read more: Significance Of Polymers

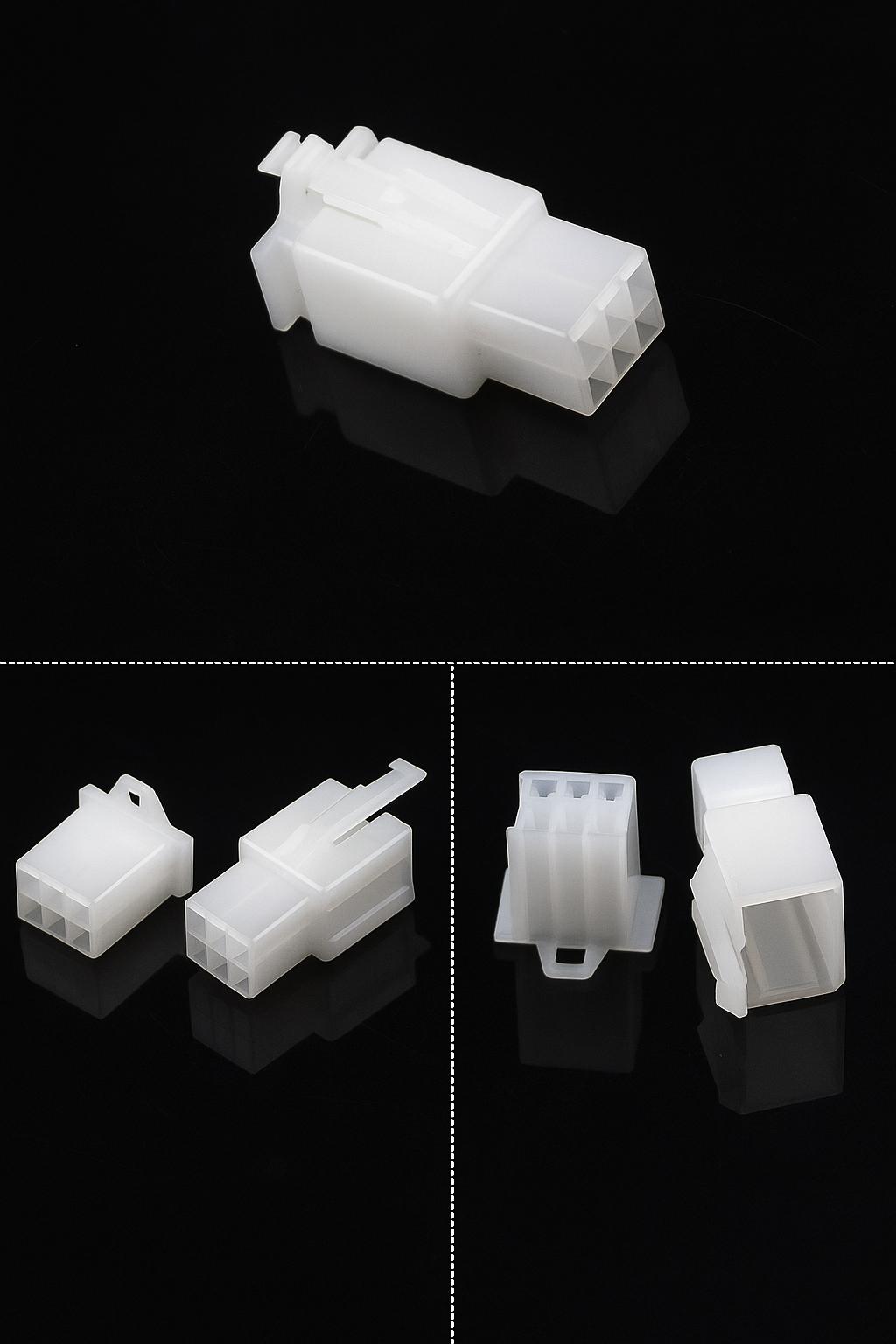

Sun Polymers is a leading polymer supplier in India, and its products, are used in industries like automotive, construction, electronics, agricultural equipment, medical equipment, etc. Sun Polymers is also HDPE raw material suppliers offers a wide range of polymers like ABS, SAN, NYLON 6, NYLON 66, PBT, PC, GPPS, HIPS, TPU, LD, HD, PP, PPCP, EVA, etc., which helps our clients find the exact solutions they are looking. As Nylon 6 dealer in Chennai, we have advanced production lines and complete testing equipment to ensure the consistent quality of our products. With over two decades of operation, the plastic raw material supplier in India has worked with virtually all engineering polymers, including the five basic types of engineering polymers: polyphenol, polyester, polyoxymethylene, polyamide, and polycarbonate.

Engineering polymers help to bring down the weight of automobiles by a considerable amount, so much that 20 per cent of the automobile weight is of polymers, which is roughly 300 kilos. As a result, fuel consumption and reduced greenhouse gas emissions. Polymers also contribute to automobile safety, reduce the overall manufacturing cost of automobiles, and play a vital role in designing automobiles. Simply cutting 100 kilos of weight from an automobile will reduce CO2 emissions by roughly 10 g per km and save you around 0.4 litres per 100 kilometres.

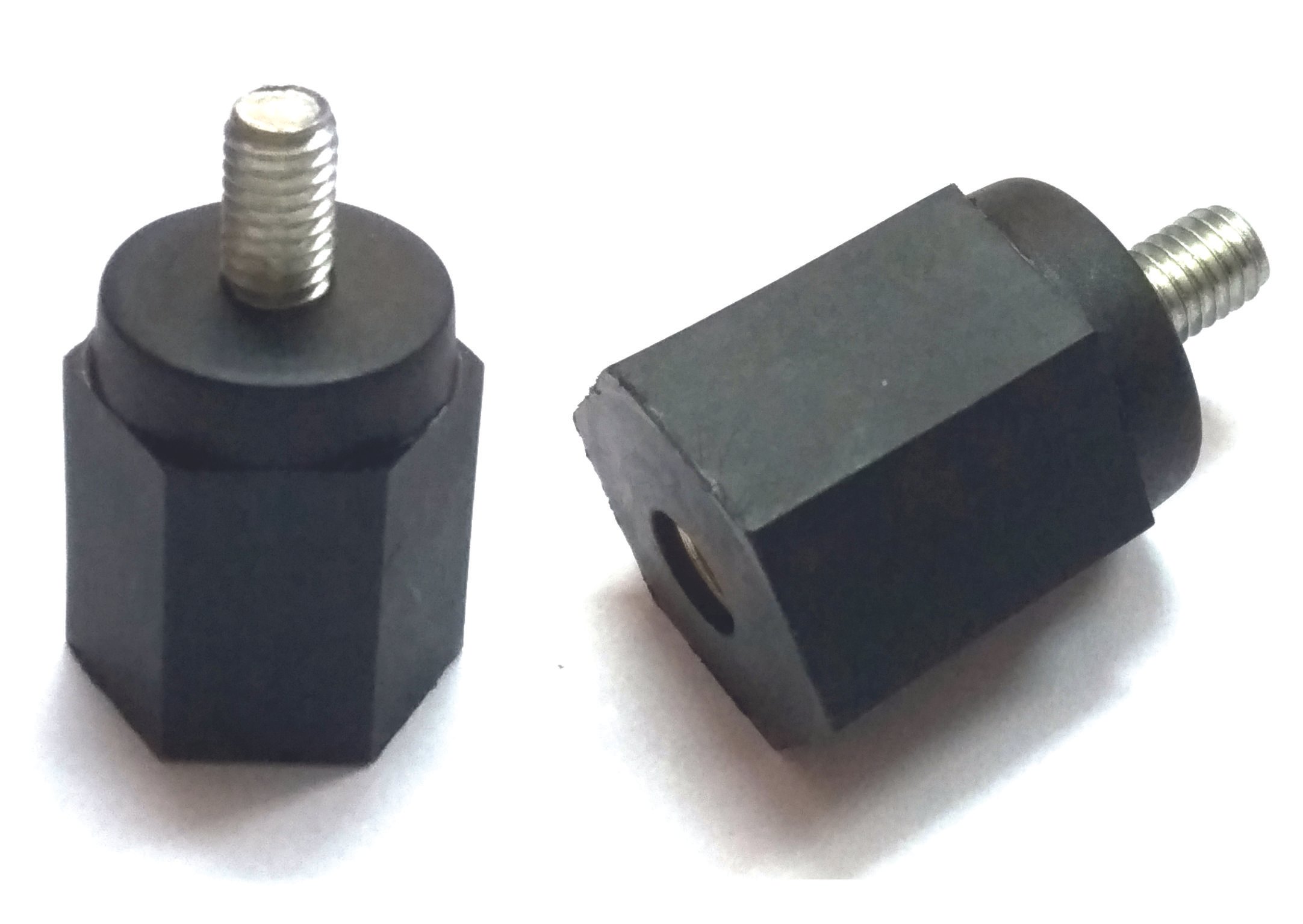

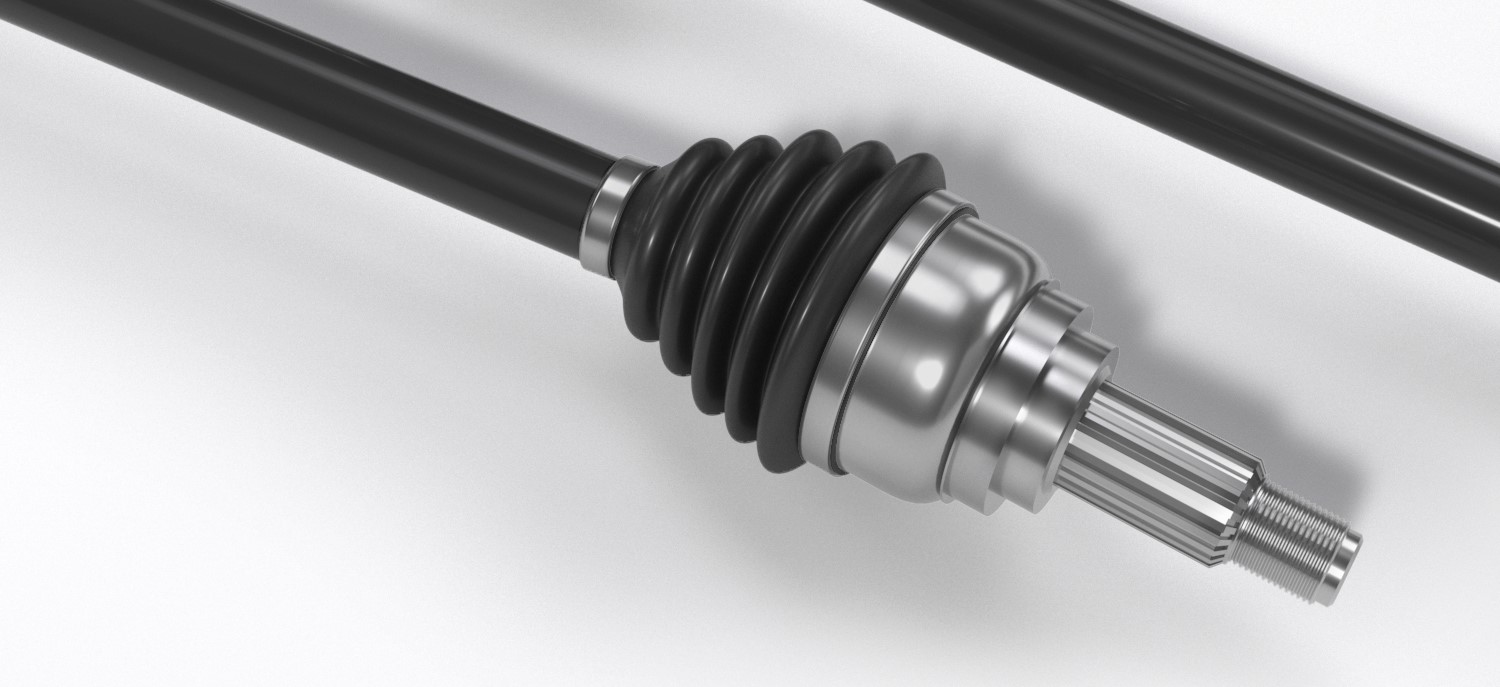

Bumpers made from polycarbonate (PC), Acrylonitrile Butadiene Styrene (ABS), polyurethane (PUR), polypropylene (PP), and polyamide (PA) compounded with glass fibres are five times more impact resistant and also weigh half of those made of other materials. Polyamide airbags and seat belts made from durable polyester fibre have made automobiles much safer to travel in. A thin layer of PVB or EVAC sandwiched between two glass layers prevents laminated glass windshields from shattering and is much lighter and stronger than tempered glass.

The assembly time of automobiles has significantly dropped due to single-mould components. Fuel tanks made of high-density polyethene (PE-HD) are unaffected by the corrosive environments in and around the tank. These tanks are also very secure during collisions as they are a single piece without any seam soldering.

Due to its ability to mould with ease, manufacturers will find innovative ways to create endless designs using polymers. Paint Protection Film has already replaced traditional automotive paints. PPF is a thermoplastic urethane film that is fifteen times tougher and offers superior resistance to scratches, UV, chips, and degradation. The PPF also does a better job of retraining a high-gloss shine.

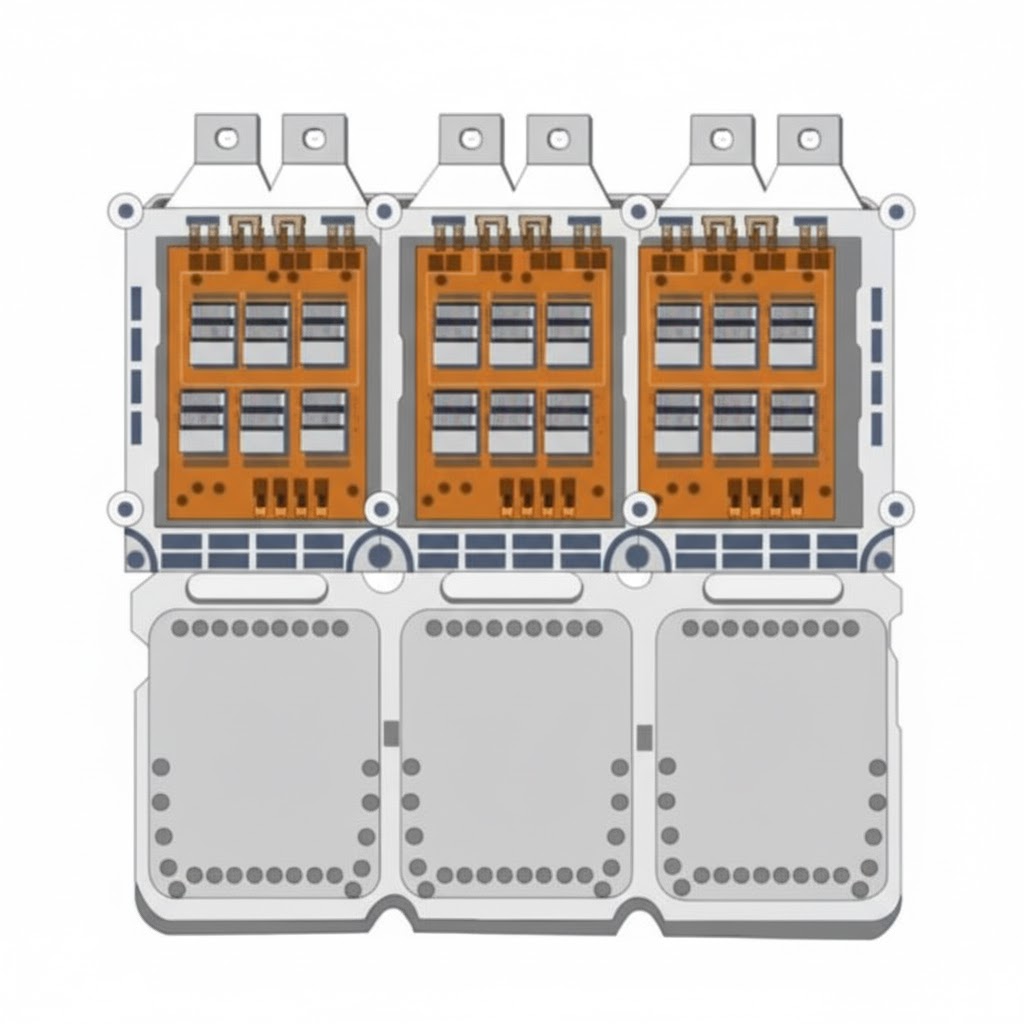

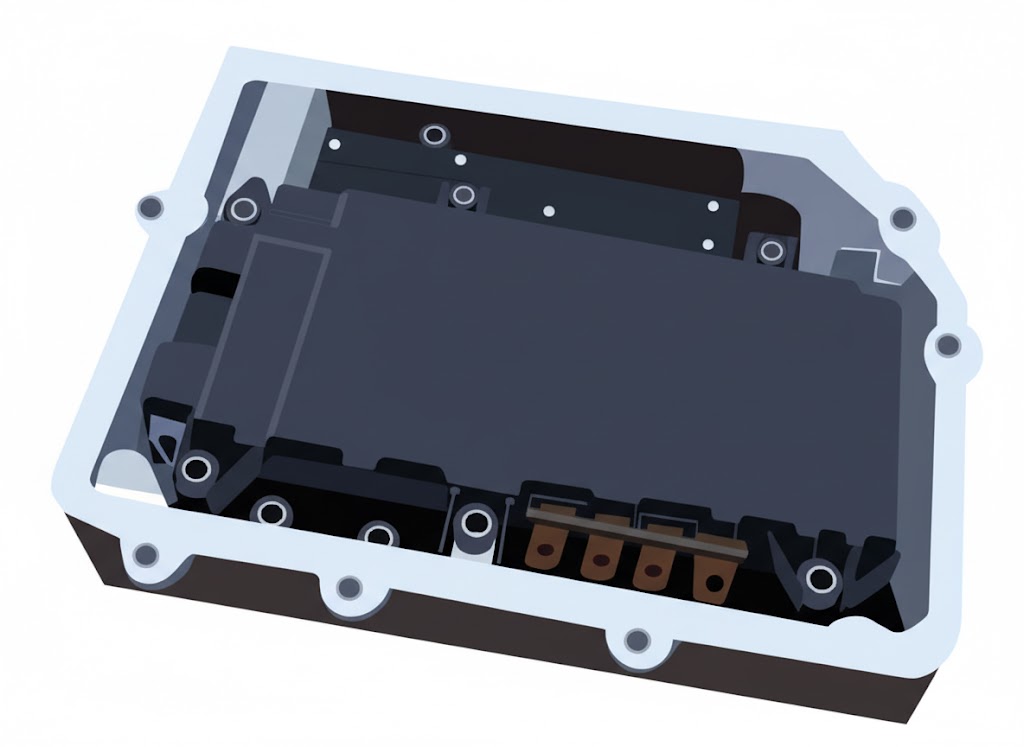

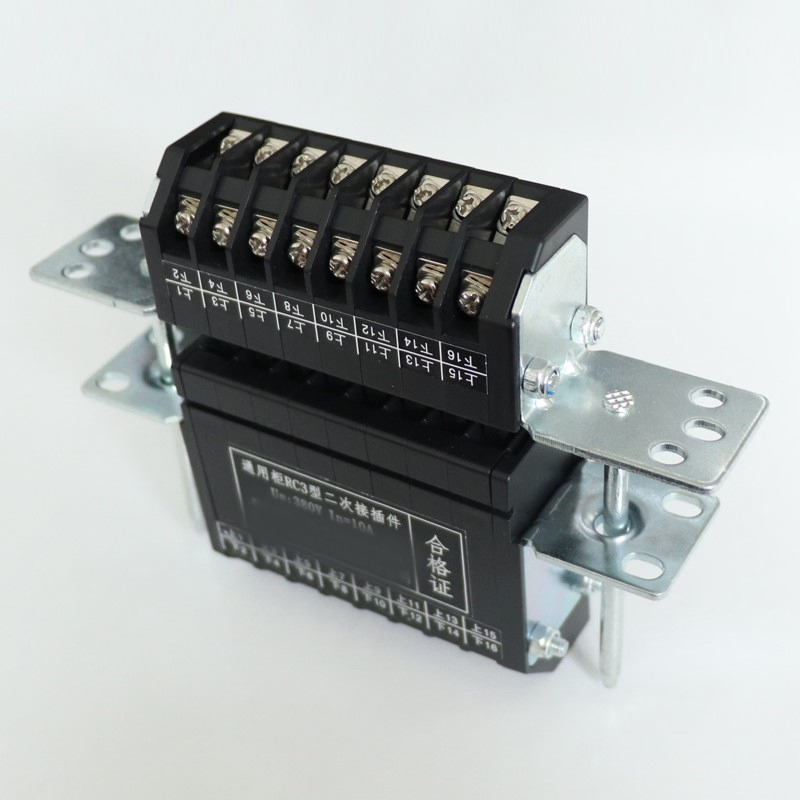

Applications of polymers don’t end here, as they are also contributing to manufacturing components for electric, hybrid, and hydrogen-powered automobiles. These components include fuel cells to power hydrogen cars and lithium-polymer batteries that are smaller and do not heat much. Fuel cells will be a common phenomenon in the coming years, and they will supply the transport sector with much-needed renewable energy. Polymer trading companies in India have already begun to provide the automobile industry with recycled and renewable plastics that they integrate into automobile manufacturing.